Real-Time Monitoring to Reduce Scrap and Waste

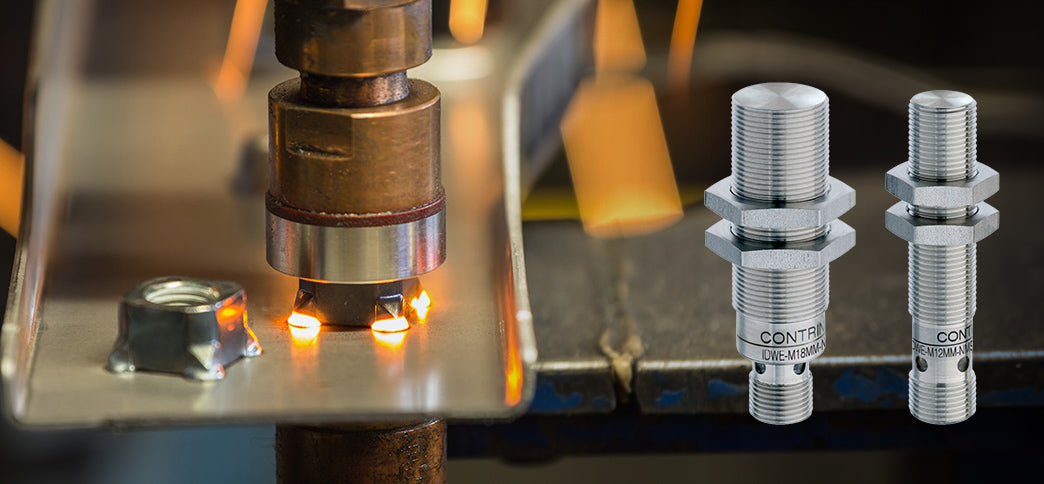

In metal-forming manufacturing, missing or improperly fastened nuts can lead to defective assemblies, resulting in costly scrap and rework. Traditional quality control methods often identify these issues too late in the process. Smart Measurement Nut Detection Sensors offer a proactive solution, instantly detecting missing or misaligned nuts in real-time. By addressing defects immediately, manufacturers can significantly reduce waste, cut costs, and enhance overall production efficiency.

Minimize Downtime and Maintain Workflow

Production interruptions can be costly and disruptive. Smart Measurement Nut Detection Sensors integrate advanced sensors that identify errors instantly, allowing operators to take corrective action without halting the entire production line. This real-time error detection minimizes downtime, ensures production schedules stay on track, and maximizes operational efficiency.

Improve Quality Control with Precision Detection

A common challenge with automated detection systems is the occurrence of false positives, leading to unnecessary scrapping of good parts. Smart Measurement Nut Detection Sensors utilize advanced algorithms to differentiate between genuine defects and false alarms. This precision ensures that only defective parts are flagged, improving quality control, reducing waste, and enhancing customer satisfaction.

Seamless Integration with PocketCodr for Easy Setup

Optimizing Smart Measurement Nut Detection Sensors is easier than ever with PocketCodr. This intuitive tool simplifies sensor setup and calibration, allowing operators to configure detection systems efficiently without the need for specialized technical expertise. With user-friendly controls, PocketCodr enhances the effectiveness of smart detection solutions, maximizing productivity and ease of use.

Learn more about our Smart Measurement Nut Detection Sensors here