Precision, safety, and efficiency are crucial for successful automated production. Contrinex offers two exceptional sensor solutions—Inductive Miniature Sensors and Photoelectric Miniature Sensors—to tackle the challenges of handling delicate components and preventing costly collisions in robotic gripper systems.

Solution 1: Inductive Miniature Sensors Safeguard Fragile Components

In various industries, maintaining the integrity of delicate materials during production is a top priority. One example is solar cell manufacturing, where fragile silicon wafers are transported using two-finger robot edge-grippers. If the gripper jaws are not fully open before descending, the wafers risk damage, resulting in costly scrap and production delays.

The Contrinex Solution:

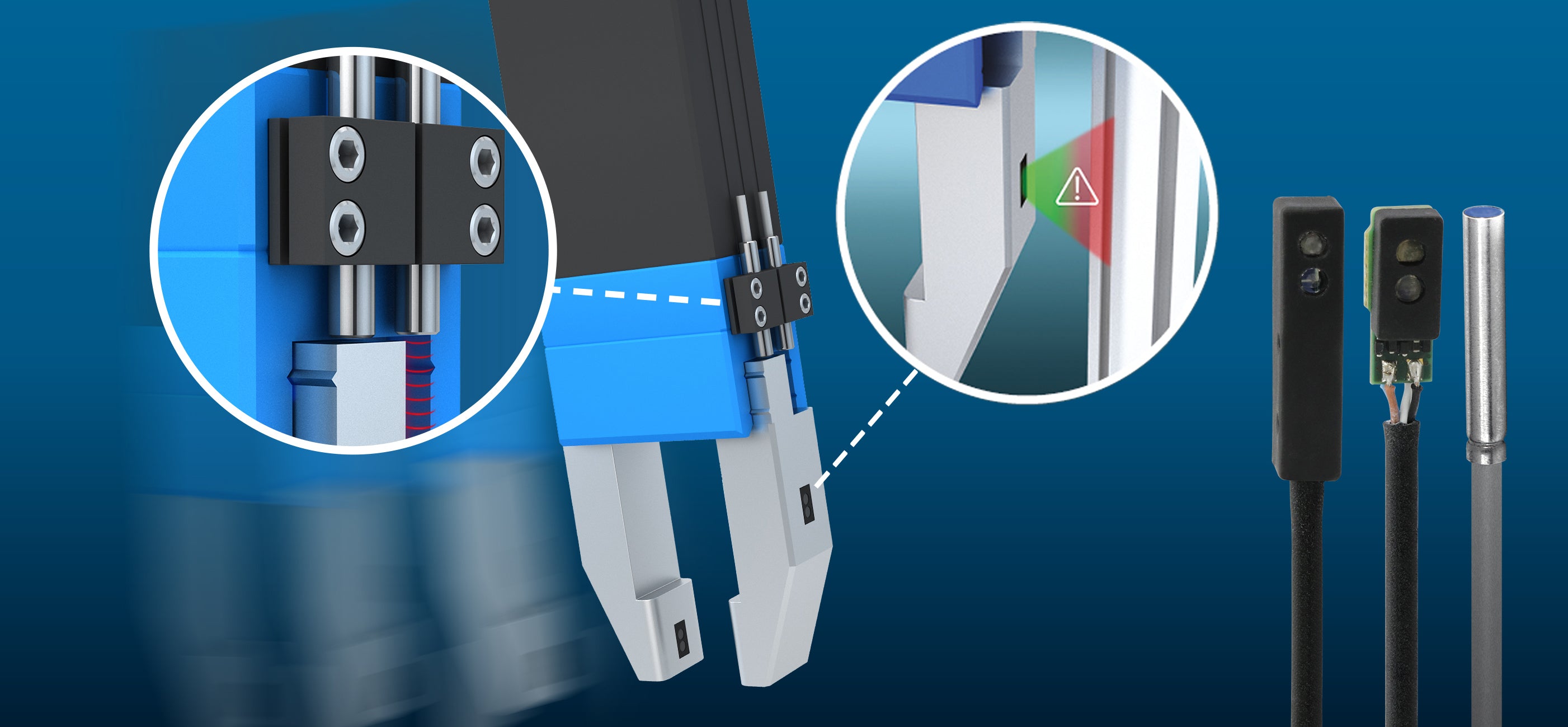

Inductive Miniature Sensors, positioned above the gripper jaws, detect when the jaws are fully open, ensuring precise operation and protecting delicate components. With a compact 3mm diameter and 22mm length, these robust sensors fit effortlessly into restricted spaces and deliver reliable, non-contact detection.

Key Benefits:

Damage Prevention: Verify fully open gripper jaws, avoiding component damage.

Compact Design: Stainless steel housing (3mm × 22mm) fits tight spaces.

Reliable Compatibility: Industry-standard PNP/NPN outputs with NO/NC options work with diverse systems.

Broad Operating Range: Functions seamlessly in temperatures from −25°C to +70°C.

Maintenance-Free: Fit-and-forget operation ensures uninterrupted throughput.

While this application highlights their use in solar cell manufacturing, Contrinex Inductive Miniature Sensors can be adapted for a wide range of applications requiring precise detection in compact spaces.

Solution 2: Photoelectric Miniature Sensors Ensure Collision-Free Operation

Avoiding collisions between robotic systems and their surroundings is critical to safety and productivity. For instance, in electronic equipment assembly, multi-finger robotic grippers transport components, but unexpected obstructions such as other robots or human interventions can lead to collisions.

The Contrinex Solution:

Photoelectric Miniature Sensors, embedded in the gripper jaws, detect obstructions in real time, preventing accidents. These housing-free sensors measure just 4mm × 4mm × 11mm, making them ideal for tight spaces where traditional devices may not fit.

Key Benefits:

Accident Prevention: Real-time obstruction detection prevents collisions.

Versatile Sensing: A sensing range of up to 40mm accommodates various operational needs.

Flexible Output: Industry-standard PNP analog output (0.3V–3V) supports precise adjustments.

Lightweight and Durable: At only 3.1 grams, these vibration-resistant sensors are reliable in dynamic environments.

Effortless Integration: Compact, unobtrusive design allows seamless installation.

The electronic equipment assembly scenario is just one example of how Contrinex Photoelectric Miniature Sensors can enhance safety and efficiency. These sensors are suitable for numerous applications requiring real-time detection in compact environments.

Explore Contrinex’s cutting-edge sensor solutions:

Inductive Miniature Product Range Page

Photoelectric MiniDist Product Range Page, with housing and without housing