Summary

Smart inductive sensors provide automation engineers with affordable high-precision position-control options for linear stages.

Automation engineers designing high-speed assembly equipment with multiple linear transfers between workstations need to maximize speed and accuracy while keeping cost down. They require a single-sensor positional-control solution that delivers a high-speed approach to the critical areas and a slower, high-precision final positioning. Designers specified inductive Smart Sensors from Contrinex; a single sensor with IO-Link connectivity and multiple user-configurable outputs performs both the required tasks in a highly cost-effective manner.

Customer Benefits

- Rugged inductive Smart Sensors ensure accurate positioning of linear stages without compromising operational speed

- Single-sensor positional-control system is non-complex and highly affordable

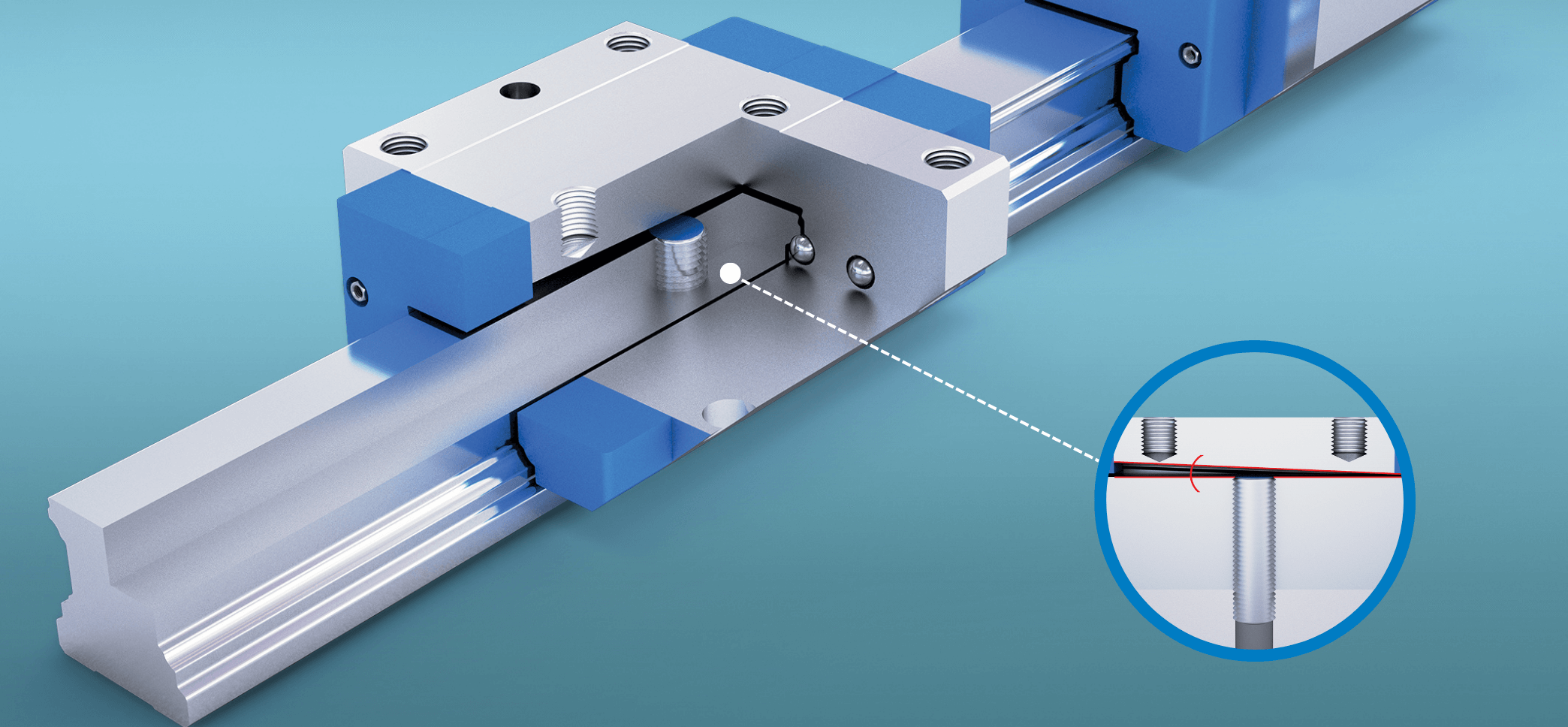

- Compact embeddable M12 sensors fit unobtrusively and easily into off-the-shelf linear guide rails

- Industry-standard IO-Link connectivity provides a single interface to the machine control system.

- Sensor configurations are stored locally, allowing plug-and-play replacement of sensors when needed.

- Proven technology ensures highly reliable fit-and-forget operation with no manual intervention

Specific Product Advantages

- Robust, metal-cased inductive Smart Sensors are ideal for easy integration

- Multi-channel monitoring circuitry allows users to define up to nn customized output thresholds

- Sophisticated sensing electronics deliver dynamic linear-distance measurements with a resolution in the micron range

- On-board data storage holds cumulative operating data for user-specified purposes, including predictive maintenance

- High-speed device-to-device communication enables decentralized data-processing and decision making

- Dedicated service-data blocks hold device-specific data including product ID, location and serial number

- Visible LED indicators enable sensors to self-identify on demand, simplifying commissioning and trouble-shooting routines

- Industry-standard -25°C to +70°C operating range