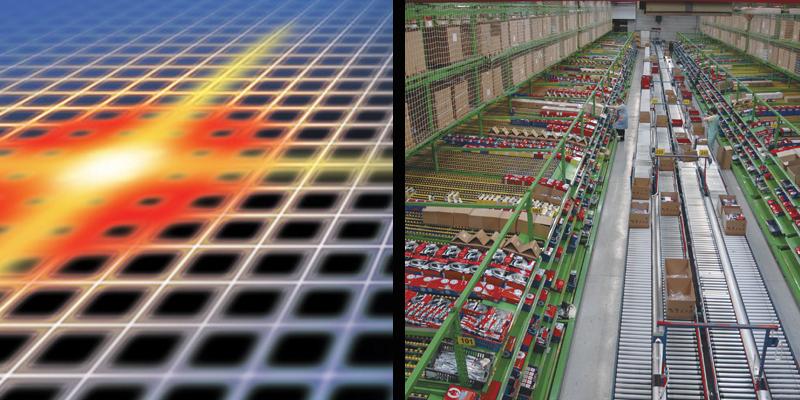

The use of infrared light grids for non-contact measurement offers many advantages, including fast response times, reliable detection of the most varied objects and immunity to interference from ambient light. Potential applications for these keen-eyed, robust sensors are to be found in such fields of application as logistics or automated packaging systems and in harsh environments such as warehouses and the wood industry.

With the DGI (detection) and MGI (measurement) series, Contrinex presents compact infrared light grids as a robust plug-and-play solution. With a cross-section of only 40 x 20.5 mm, these space-saving devices are easily integrated into different systems. DGI types offer detection heights up to 2010 mm and are capable of detecting objects with diameters of 0.9, 2, 4, 8 or 25 mm, depending on type. With response times between 0.8 and 4.8 ms, even small objects moving at high speed can be reliably detected and counted. Fields of application include the production of small parts or foil, packaging equipment and the pharmaceutical industry. In addition to detecting the presence of an object, MGI measurement types can also determine its dimensions and position. These sensors offer measurement heights up to 1438 mm and a resolution of 5 or 12 mm. Measurements are output as analog values of 0-10 V or as a 4-20 mA signal.