Summary

Light curtains are used on a hydraulic press prototype to protect operators from possible injury. The prototype was built by the Institute for Fluid Power Drives and Controls at Aachen Technical University to demonstrate a component testing development environment for Germany’s Federal Ministry of Education and Research. It was presented at HMI Hanover Trade Show.

Customer Values

- Meets highest safety requirements economically

- Reliable and adaptable

- Easy to install

- Fail-safe electronic design

Specific Product Advantages

- Certified CE, TÜV, and UL

- IP 65 and IP 67 class protection

- Category 4, PL e according to EN/ISO 13849-1

- Type 4 according to EN/IEC 61496-1 and -2

Customer Application

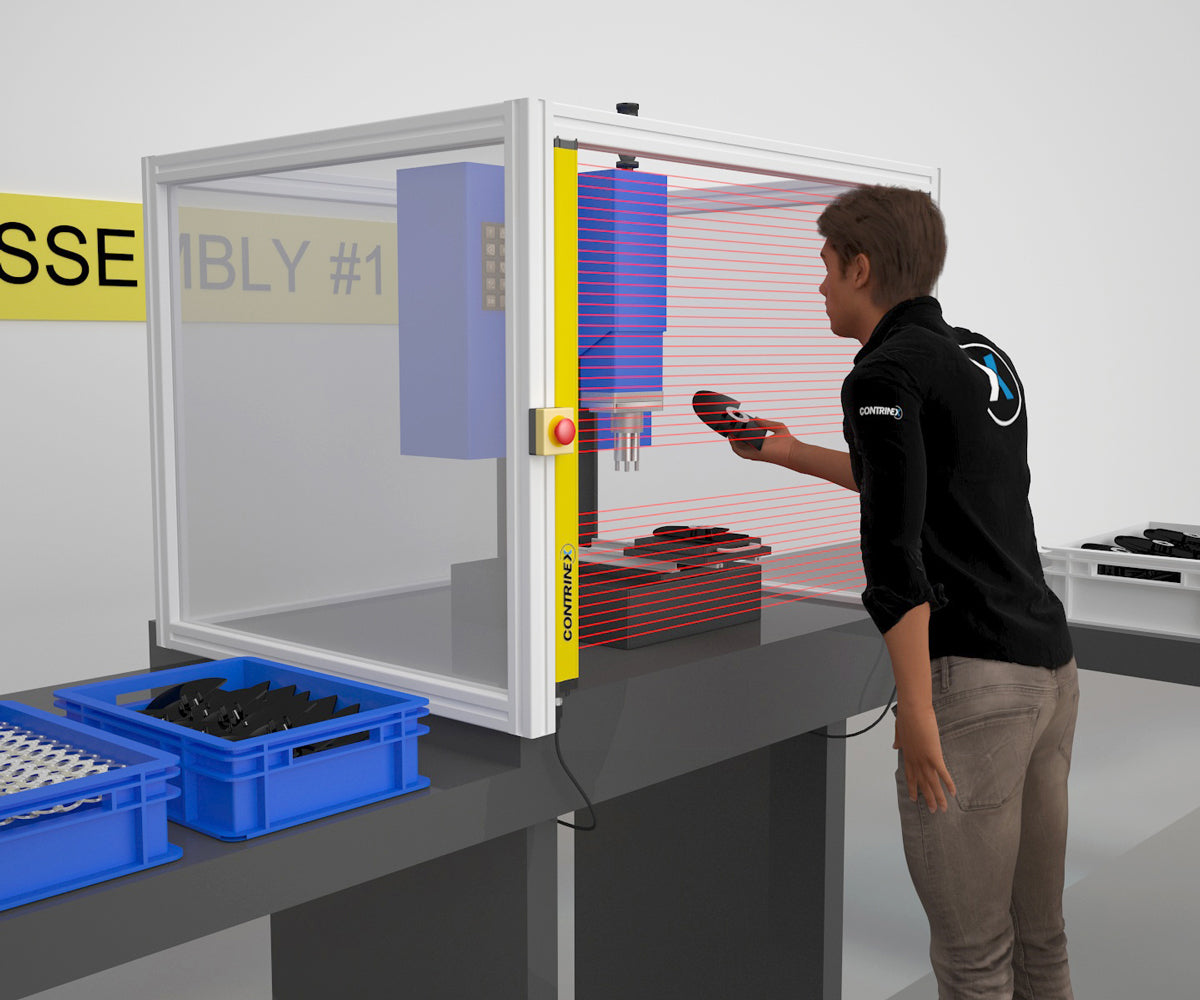

The development environment simulates an entire system and tests interactions between all its specified components at the earliest design stage possible, before some have even been produced. To test and demonstrate this ‘hardware in the loop’ simulation, engineers built a prototype hydraulic press. Good visibility and reliable, fail-safe protection for the operators are essential. The protective device chosen must also ensure that the prototype represents a standard machine in a real situation.

This hydraulic press is suitable for an optical safety solution, since any dangerous movement can be stopped at every defined operating phase. In addition, there is no risk of injury due to material ejected during its operation.

Customer Solution

Safetinex YBB safety light curtains satisfy the demands of this potentially dangerous application. They meet safety category 4 of EN ISO 13849-1 as well as type 4 of DIN EN 61496-1 and -2.

The safety light curtain comprises a sender and a receiver unit. Infra-red beams create a protective field. .The chosen resolution of 14 mm is suitable for finger protection and has a maximum operating range of 3.5 m. LED displays on the sender and the receiver indicate field status, operating mode, transmission channel, and alignment quality.

If any object enters the protective field, the press stops immediately. The reliability of this protection system is guaranteed by a fail-safe electronic design with permanent autocontrol.