Summary

Plastic containers, filled with liquid food products, are hermetically sealed at a Portuguese food-processing plant. Prior to containers being capped and packed in bulk, in-line testing confirms that each one has been correctly sealed. A long-distance inductive sensor, positioned directly over the packaging line, senses the presence of an aluminum-foil seal over the top of each container.

Customer Values

- Reliable, repeatable in-line testing of a range of different-sized containers

- Testing is completed without difficulty at production-line speed

- Immediate identification of containers with missing closures

- Elimination of manual inspection and potential batch rejection

Specific Product Advantages

- Extended sensing distances up to 40mm

- Unmatched combination of 40mm sensing distance in M30-diameter device

Customer Application

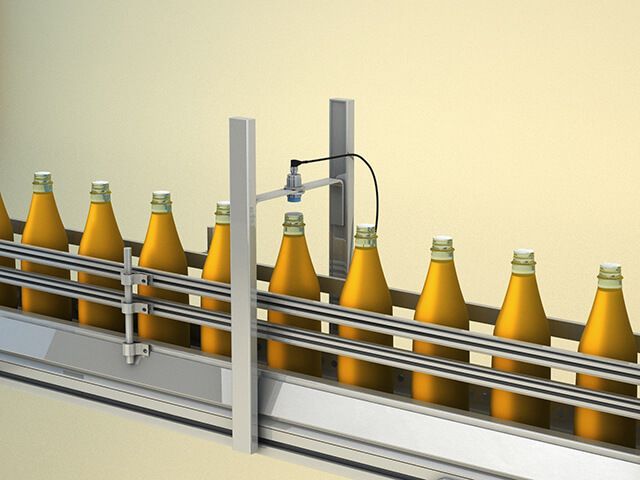

Aluminum-foil closures are commonly utilized as seals for plastic containers filled with mustard, ketchup and other table sauces. At a Portuguese food-processing plant, closures are applied to filled containers passing along an automated production line, sealing the contents ready for capping and bulk packaging.

From time to time, equipment malfunctions occur and containers leave the sealing station without closures in place. If unsealed containers are not detected prior to capping, entire batches of product may require manual inspection, resulting in lost production, down-time and potential rejection by customers.

An in-line sensor system must inspect each container and detect the presence of a foil closure, rejecting any faulty items. Each line processes containers in batches; successive batches may comprise filled containers of differing sizes. The system must accommodate containers whose heights vary by up to 20mm, without positional adjustment of sensors between batches.

Customer Solution

Contrinex Extra Distance inductive sensors are ideal for this application. M30-diameter units from the range operate reliably at sensing distances up to 40mm; a single sensor thus accommodates the entire range of container heights. Robust construction with chrome-plated brass bodies and PBTP sensing faces ensures that these devices are suitable for a busy production environment.

A single sensor, located immediately after the sealing station and positioned directly above the production line, provides reliable, repeatable detection of the aluminum-foil closures. With a switching frequency of up to 100Hz, this Extra Distance unit is well suited for fast-moving production where high-speed sensing is required.

This Contrinex inductive sensor has an industry-standard PNP normally-open interface and an integral M12 cable connector, allowing easy removal and replacement of individual sensors for maintenance. Connection to the customer’s test equipment is via a flexible PVC-sheathed cable.

With an unmatched combination of 40mm sensing distance in an M30-diameter device, the customer can now test the entire range of containers without adjusting the sensor height between batches. Contrinex Extra Distance inductive sensors deliver exceptionally reliable test results at production-line speed, without interruption.