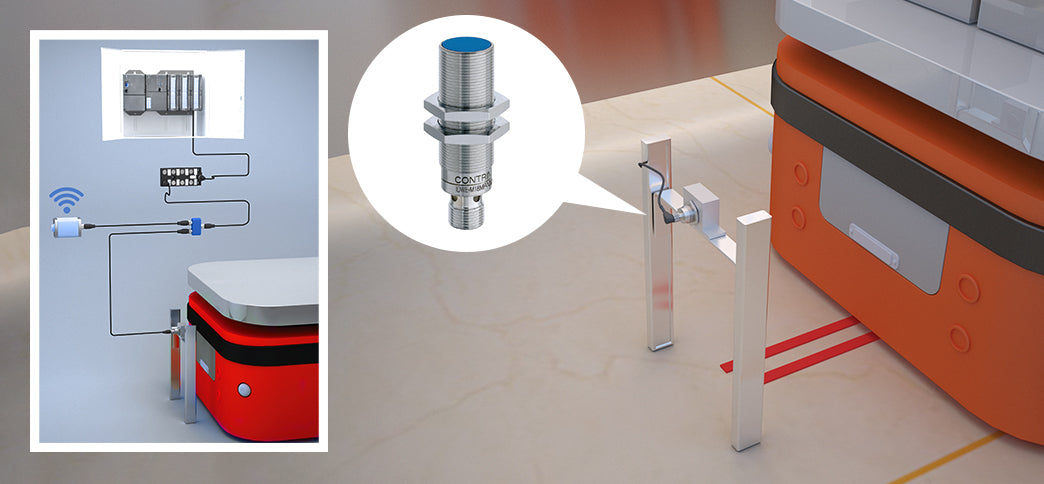

An inductive Basic Smart Sensor, positioned in the docking bay of a pick-and-place loading machine, senses the approach of an AGV and communicates via IO-Link with a central PLC, ensuring safe two-speed docking. Using its second output, the sensor also communicates with a local control system via a wireless hub, initiating start-up for the pick-and-place machine, which has been on stand-by since completion of the previous loading cycle.

Local optimization of machine utilization and energy usage optimizes effectiveness

- Smart inductive sensor supports two-speed AGV docking to reduce cycle time

- Simple IO-Link routines trigger low-speed final approach at pre-set distance

- Secondary output communicates wirelessly with local control systems

- Machine standby is initiated and ended based on demand, reducing energy needs

View Smart Inductive Basic Sensors here

View Smart Sensor Brochure here