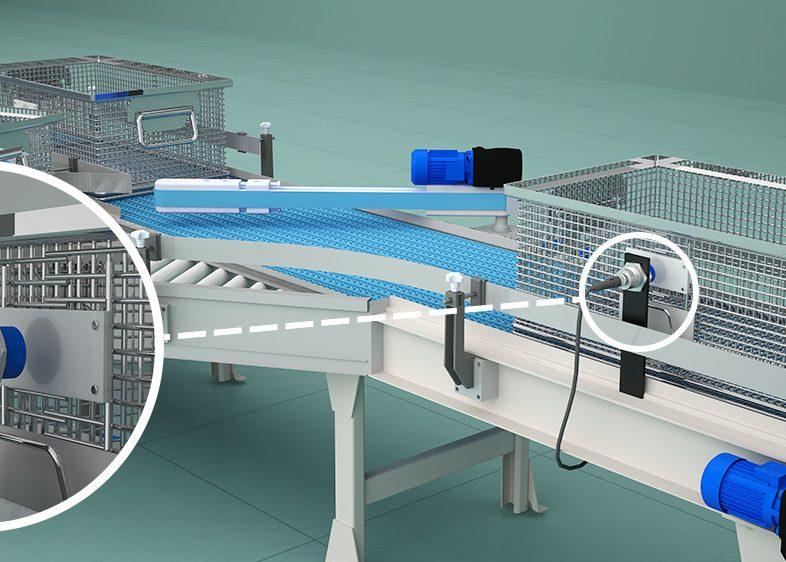

A manufacturer of automated conveyor systems uses RFID technology to monitor the location of items and to route them to their chosen destinations. As an item, fitted with an RFID tag, travels through the warehouse, IO-Link-enabled high-frequency read-write modules (RWMs) monitor its position and read pre-set data stored in the tag. Local logic capability enables a RWM to trigger a conveyor diverter, routing the item without reference to a centralized PLC-based control system.

Customer value

- Industry-standard IO-Link interface ensures reliable out-of-the-box connectivity

- Two modes of operation in a single read-write module provide ultimate flexibility

- Standard I/O mode operation supports operation of decentralized sorting systems

- Plant-wide IO-Link hardware simplifies system integration

- Commonality of RWM hardware minimizes spares inventory holding

- Integral M12 connectors ensure easy installation and replacement

Specific product advantages

- IO-Link V1.1 compatibility

- Robust metal housings with PBTB sensing faces

- Sensing distances up to 60 mm

- Reconfigurable remotely or via Master Tag

- Smart condition-detection sensor in SIO Mode