Summary

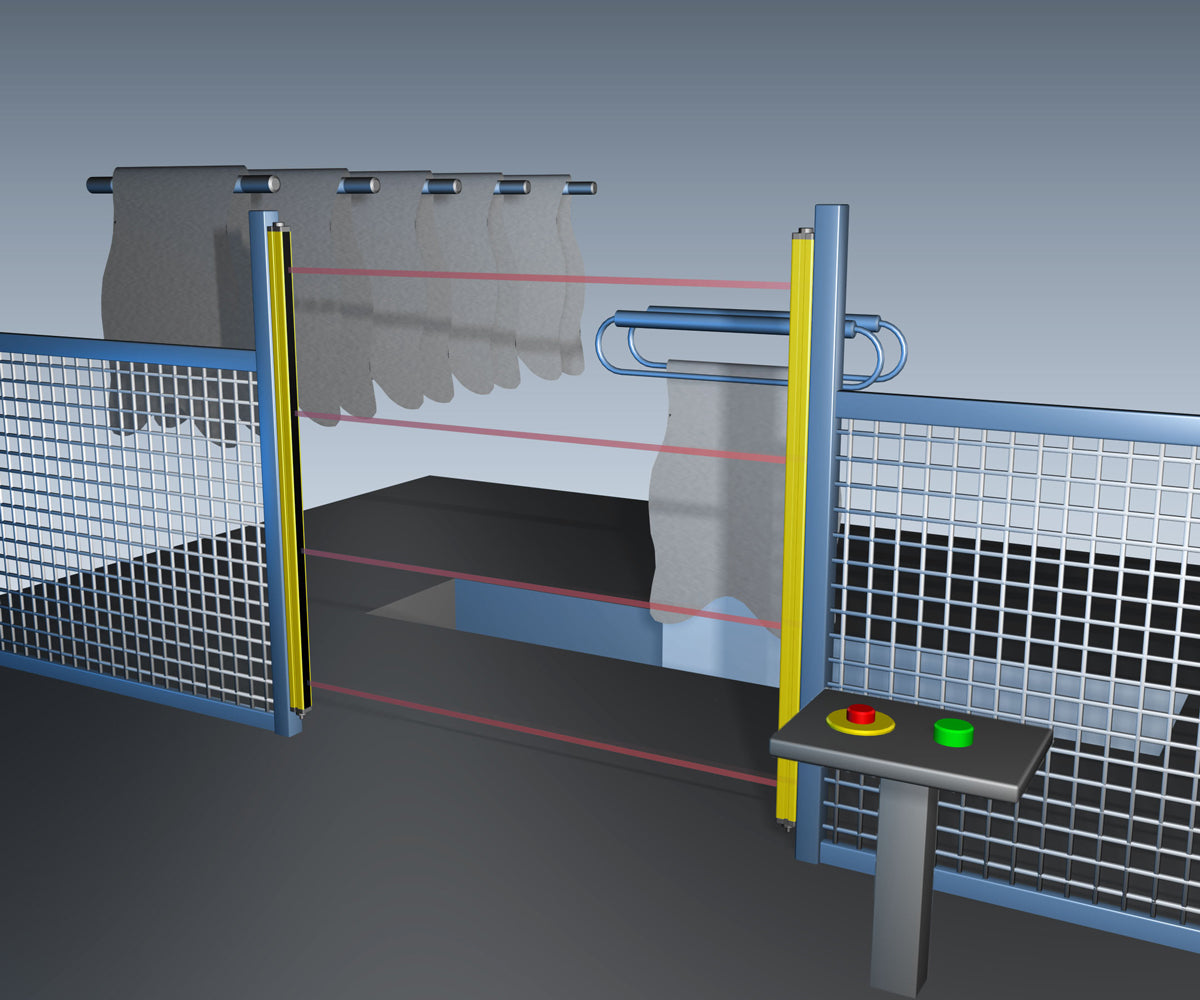

A tannery uses Safetinex access control barriers to protect the entrance to its automated stock handling area. Safetinex access control barriers detect any operator entering the area and stop the leather stock moving at high speed in the automated handling system. Furthermore, damage to company vehicles and the stock handling installation itself is also avoided.

Customer Values

- Meets highest safety requirements economically

- Reliable, adaptable, easy to install and maintain

- Fail-safe electronic design

- Permanent autocontrol

Specific Product Advantages

- Certified CE and TÜV

- IP65 and IP67 class protection

- Category 4, PL e according to EN/ISO 13849-1

- Type 4 according to EN/IEC 61496-1 and -2

Customer Application

A new machine has the job of placing test-tubes in racks. To achieve this, bulk fed test-tubes are placed separately on a conveyor and then pushed into the sample racks. It is crucial that the test-tubes enter the racks the right way up. The cap sealing each small tube must be uppermost. However, the orientation of these blood test-tubes on the conveyor line is random – sometimes the cap is to the right, sometimes to the left.

The form and material of blood test-tubes makes measuring them quite problematic. They are round, transparent and filled with liquid in varying quantities. The contours are indistinct and there is a lack of plane surfaces. These are major challenges for most principles of measurement. However, instead of a solution based on laborious and costly camera-based systems or profile scanners, the customer seeks a method that will deliver results quickly and reliably, but also economically.

Customer Solution

Series 3130 analog reflex sensors with protection class IP 67 provide the solution that suits this medical environment.

Test-tubes lying on the conveyor pass under a lightweight lever. This traces the contour of the test-tube, rising or falling accordingly. The side of the lever facing the photoelectric sensor is a plane surface, guaranteeing absolutely reliable measurement. The sensor detects the fitted cap by its 1 mm elevation above the test-tube. Every 20 ms, the controller polls analog signals from the sensor and determines the position of the cap mathematically. According to this measurement, the machine then turns the test-tube the right way up and pushes it into the rack. A test-tube without a cap is identified by the sensor as an error, since no significant bounce can be detected. In such cases the machine will be stopped. This method allows the equipment to handle one correctly orientated test-tube per second.