Summary

Tool changers for industrial robots improve productivity by creating multi-functional machines with rapid tool interchangeability. During changeovers, sensor-based systems must ensure that end-effectors are completely secure – with minimal loss of productive time. Contrinex MiniMini inductive sensors detect the presence of a tool carrier and sense the position of the locking mechanism, ensuring that changeovers proceed swiftly and safely. These robust devices offer a reliable, cost-effective solution to the problem.

Customer values:

- Ultraminiature embeddable MiniMini inductive sensors minimize loss of productive time, safely and repeatably

- Compact 3mm-diameter x 22mm V2A (AISI 303) stainless-steel housing allows easy integration in tight spaces

- Sensing distance of 1mm offers designers attractive alternatives when specifying equipment

- Industry-standard PNP and NPN outputs with normally open or normally closed options interface easily with a wide range of control systems

- Proven technology provides a highly reliable, robust, cost-effective solution to the problem

Product Specific Advantages:

- Miniature stainless-steel inductive proximity sensors suitable for easy integration

- PNP and NPN interface with NO and NC options and minimal power consumption

- Sensor weight only 25 grams with a compact 3mm-diameter x 22mm housing

- PNP devices feature IO-Link connectivity, providing increased functionality and flexibility

- Industry-standard -25°C to +70°C operating range

- Reliable, compact vibration-resistant sensors

Customer Application

Tool changers for industrial robots are proven to improve productivity by creating multi-functional machines with rapid tool changeovers. With a suitably sized end-of-arm tool changer, a single pick-and-place robot deploys multiple end-effectors (including grippers and vacuum lifters) during a single operational cycle, with minimal loss of productive time.

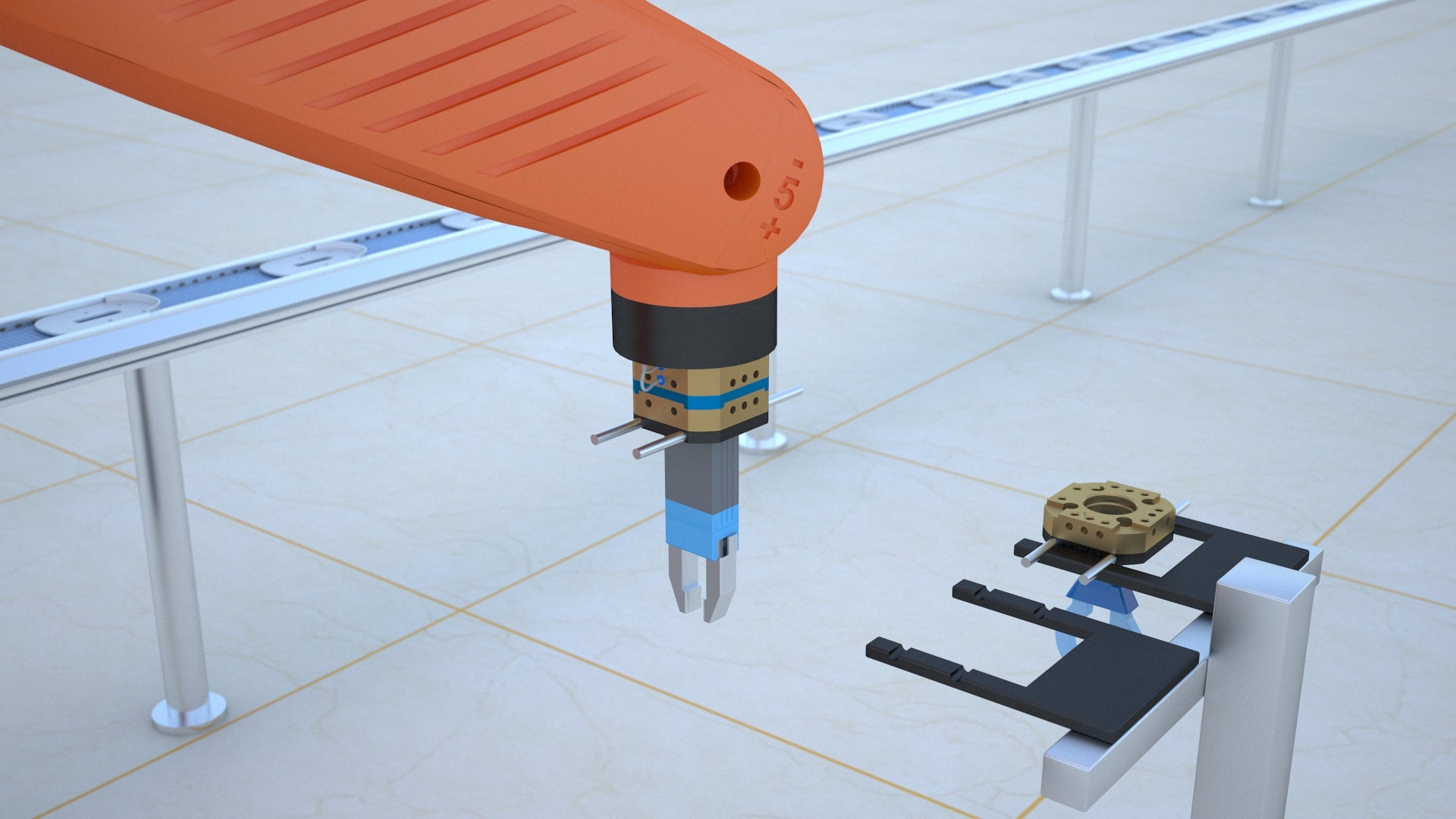

Many tool changers feature an annular ring of ball bearings that engages with a circular groove on the inside of the tool carrier. A retractable plunger, moving axially inside the changer and the carrier, locks the balls – and thus the carrier – in place. Correct engagement and locking is essential for fail-safe execution, particularly in view of the substantial load-carrying capacity of larger robots.

During changeovers, engineers require a highly reliable sensor-based system to detect the presence of a tool carrier during the final stage of engagement, and to monitor the position of the plunger. This ensures that engagement and locking (and in turn unlocking and disengagement) are correctly sequenced and that an end-effector is completely secure before the next process commences. Reliability and a small physical envelope must be matched with cost-effectiveness, giving an attractive price-performance ratio.

Customer Solution

Tough, embeddable and only 3mm in diameter, Contrinex MiniMini inductive sensors meet the requirements in full. During a changeover, a single sensor, fitted axially to an external surface of the tool changer, detects the presence of the tool carrier, inhibiting the locking cycle until engagement is complete.

Two identical sensors, embedded axially in the body of the tool changer, sense the position of the plunger and confirm a locked or unlocked state, ensuring that the robot’s operational sequence commences safely. The sensors’ small size and 1-mm sensing distance simplify their integration within the assembly, while a single M12 connector makes for seamless, simultaneous connection of all three devices.

Contrinex MiniMini devices deliver all the benefits expected from a market-leading family of stainless-steel-bodied (V2A/AISI 303) inductive sensors; not only are they rugged and resistant to vibration and mechanical shock, they’re IP67-rated and operate within an industry-standard -25°C to +70°C temperature range. These fit-and-forget devices offer a robust, cost-effective solution to the problem.

MiniMini sensors are available in PNP/NPN configurations, with a choice of NO/NC configurations. Should the customer require increased functionality in future, all PNP devices feature IO-Link connectivity, providing an easy industry-standard interface to a central control system for routine process data.