Visit us at SPS Nuremberg, Stand 430, Hall 7A, to see a live demo of this exciting technology.

Visit the Weld-immune product page here

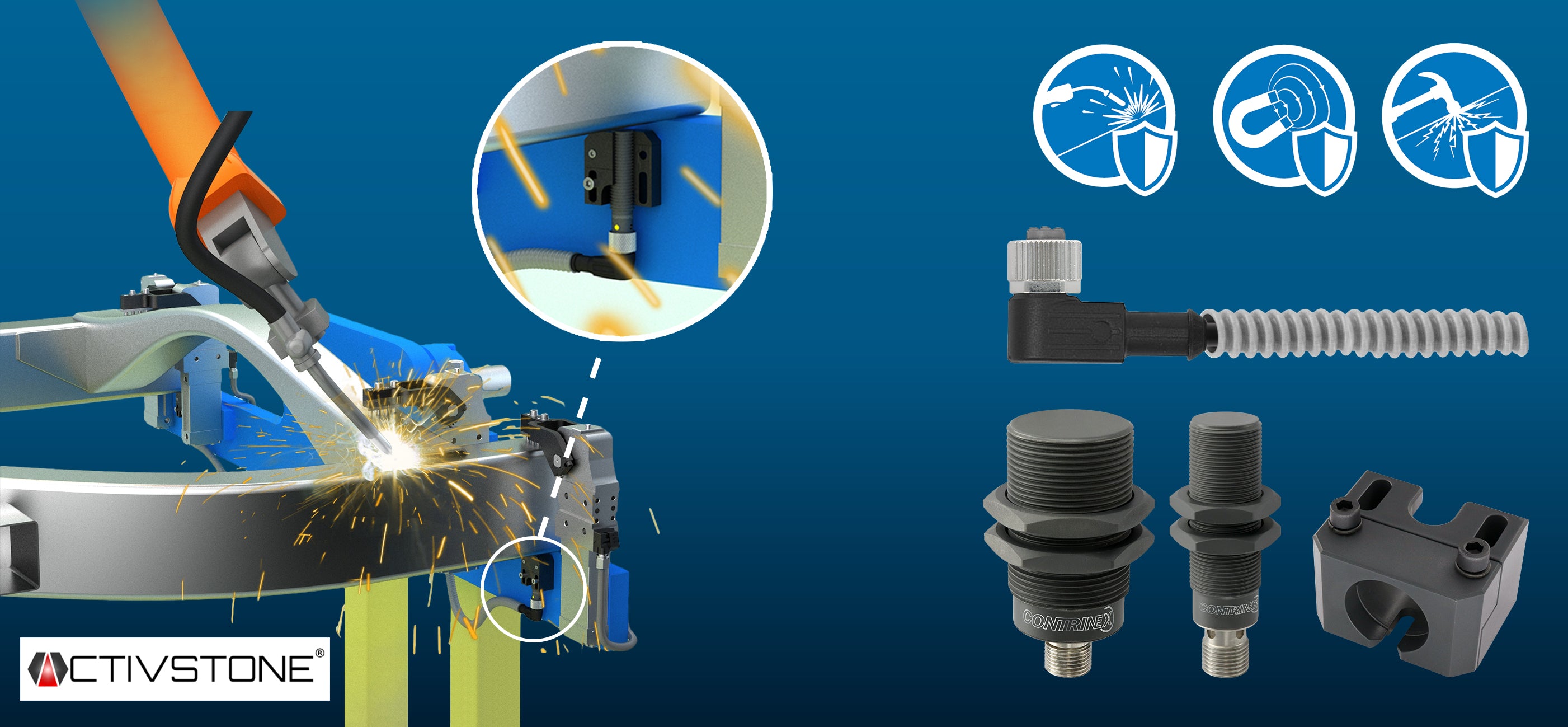

The introduction of spatter-resistant weld-immune sensors is a major step forward in improving efficiency and quality control in automotive welding. One of the key advantages of these sensors is the use of ACTIVSTONE® coating on all external surfaces, making them resistant to weld spatter in spot, MIG, and MAG applications. This not only extends their operational life but also minimizes downtime due to maintenance. These sensors also resist magnetic interference from medium-frequency weld fields and can handle currents up to 15 kA, ensuring reliable performance even in high-intensity welding environments.

Additionally, they are built with one-piece stainless-steel housings and Condet® technology, which offers maximum impact resistance—a vital feature for harsh manufacturing environments like automotive chassis welding. The ACTIVSTONE®-coated mounting brackets and spatter-resistant cables further enhance their durability and resistance to weld debris, making them exceptionally robust and low-maintenance.