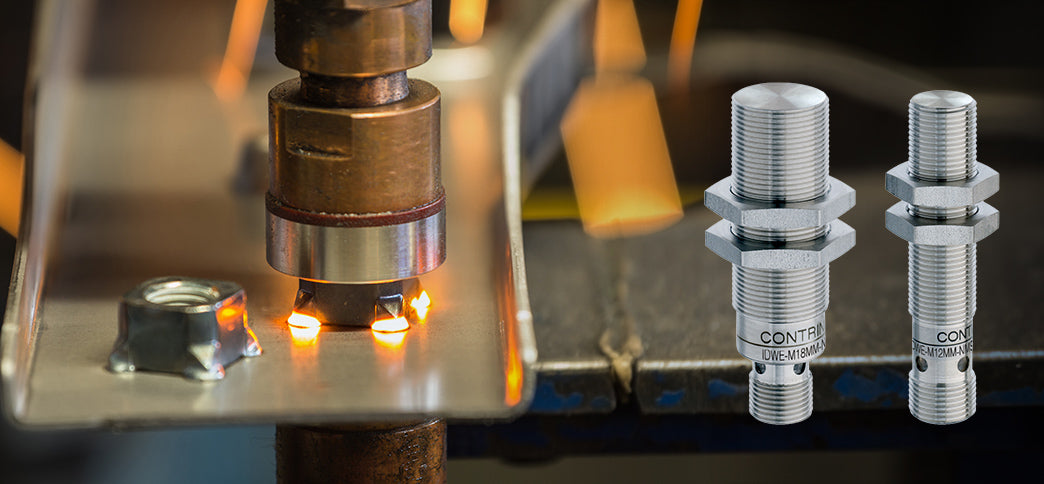

In manufacturing, every defective part represents a potential roadblock to seamless production. The use of weld nuts in sheet-metal parts is a common practice, providing threaded mounting points critical for assembling various components. However, the detection of missing weld nuts has long been a challenge, leading to costly production scrap. Contrinex Digital Measurement (DMS) Inductive Smart Sensors, ensures the presence or absence of individual nuts in real-time, bringing reliability and repeatability to assembly operations.

By using the handheld PocketCodr configurator, the process of configuring sensors for multiple panel variants becomes effortlessly simple, requiring no coding expertise or in-depth knowledge of IO-Link.

Discover the many customer benefits below:

- Robust DMS inductive Smart Sensors eliminate costly downstream scrap

- Early detection of incomplete assemblies prevents avoidable interruptions to production

- Built-in delay and timer functions prevent false positives from triggering the rejection of good parts

- Innovative PocketCodr no-code sensor configurator simplifies configuration and minimizes costs of set-up

- Individual device configurations are stored locally, allowing plug-and-play replacement of sensors when needed

- Industry-standard IO-Link connectivity enables quick, easy integration to the machine control system for process data

- Full-Inox sensors with one-piece V2A (AISI 304) stainless-steel housings are available for exceptionally harsh environments